Service Hotline

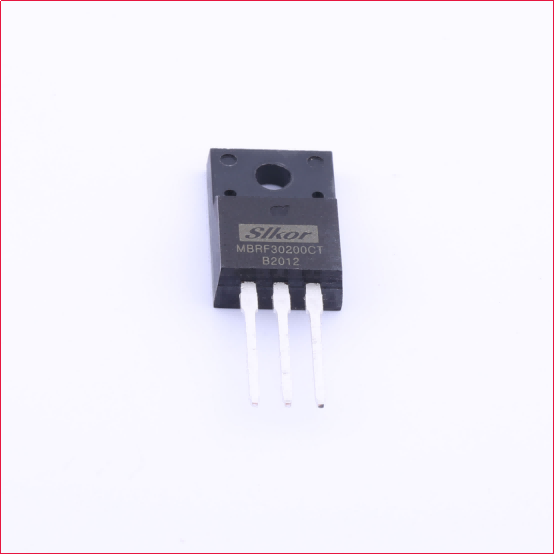

In the constant hum of 5G base stations, the precise speed control of electric motors in new energy vehicles, and the moment when photovoltaic panels convert sunlight into electricity, a silent revolution in the efficiency of power electronic devices is underway. Slkor’s MBRF30200CT Schottky diode, with its dual breakthroughs in "high-frequency low loss" and "thermal control artistry," is redefining the performance boundaries of power devices.

1. The Efficiency Key in the Era of High Frequency: The Technological Leap Behind the 1.14V Forward Voltage drop

Traditional power diodes face a paradox when switching at high frequencies—much like "having your cake and eating it too": lowering the forward voltage drop sacrifices switching speed, while increasing switching frequency leads to a surge in conduction losses. The MBRF30200CT, through innovations in material science and topological structure, achieves an ultra-low forward voltage drop of 1.14V under 30A current, while compressing the reverse recovery time to the nanosecond level.

This breakthrough has triggered a chain reaction in switching power supply designs. After adopting this device, a brand's 65W PD fast charger saw its system efficiency jump from 91% to 94%, with temperature rise reduced by 7°C. More importantly, the design team was able to increase the switching frequency from the traditional 200kHz to 500kHz, reducing transformer volume by 40% while maintaining the same efficiency, directly advancing the development of thinner, lighter fast-charging products.

In communication equipment, this high-frequency feature proves even more valuable. In 5G base station power modules, the MBRF30200CT enables MHz-level switching frequencies, shrinking the power supply size to 60% of that of traditional solutions while meeting stringent EMI standards. Engineers have aptly described it: "It turns power supply design from a 'dancing elephant' into a 'ballet dancer.'"

2. Thermal Control Artistry: The Heat Dissipation Philosophy at 200V Rated Voltage

The reliability of power devices is fundamentally a game of thermal management. The MBRF30200CT, through 3D thermal simulation-optimized packaging, reduces thermal resistance to 1.8°C/W, improving heat dissipation efficiency by 18% compared to similar products. This design brilliance is especially evident in solar inverter applications: after adopting this device, a home photovoltaic system operating continuously at 45°C ambient temperature saw a 12°C decrease in junction temperature, and the system conversion efficiency improved by 0.8%. With an annual power generation of 5000kWh, a single device’s annual additional power generation reaches 40kWh, equivalent to the carbon sequestration of two fir trees.

Industrial motor drive scenarios have tested its extreme environmental adaptability. A certain automation production line servo system, tested across a wide temperature range of -20°C to 85°C, saw the MBRF30200CT run continuously at 15A for 1000 hours, with a performance degradation rate below 1.5%. Engineers pointed out, "Its common cathode dual-pole design not only simplifies circuit layout but also achieves dynamic thermal balance through thermal coupling effects."

3. Cross-Field Technological Resonance: From Consumer Electronics to Green Energy

In new energy vehicle motor controllers, the MBRF30200CT’s 200V voltage rating and 15A rectifying capability perfectly meet the needs of 48V mild-hybrid systems. Test data from an automotive manufacturer showed that after adopting this device, the motor's response speed improved by 22%, while the control circuit board area shrank by 35%, opening new paths for vehicle electronic system integration.

In consumer electronics, this device is reshaping the power adapter design paradigm. A brand’s 100W laptop charger, by optimizing the PCB layout and leveraging the MBRF30200CT's high-frequency characteristics, integrated three traditional circuit boards into one, reducing thickness from 28mm to 18mm and cutting weight by 30%. This change not only improves the user experience but also pushes the industry towards “adapter-free” designs.

In data center power modules, its low-loss features demonstrate significant energy-saving effects. After adopting this device, a supercomputing center’s single server power supply efficiency increased by 2%. With a scale of 100,000 servers, the annual electricity savings equate to a reduction of 1200 tons of CO2 emissions. This validates Slkor’s technical philosophy: true innovation must create both economic and environmental value.

4. Design Methodology: Four Golden Rules to Unlock Performance

1. Thermal Budget Control: It is recommended to use a composite heat dissipation solution with graphene heat sinks and thermal conductive glue to ensure junction temperature does not exceed 125°C. Tests show this combination can extend the device's lifespan by 2.3 times compared to traditional solutions.

2. Circuit Topology Optimization: In LLC resonant converters, adjusting the dead-time parameters can further exploit the reverse recovery time advantage. A case study shows that optimizing the system efficiency increased by another 0.6%.

3. Layout Artistry: Implementing a "thermal-electrical separation" PCB design, where heat-generating components are separated from sensitive circuits, reduces electromagnetic interference by 12dB while improving heat dissipation efficiency by 15%.

4. Dynamic Compensation: For wide temperature applications, it is suggested to add an NTC thermistor for negative temperature coefficient compensation. Tests indicate that this measure reduces parameter fluctuations to ±3% over a temperature range from -40°C to 150°C.

5. Conclusion

As power electronic devices enter the "nanometer era," the MBRF30200CT demonstrates not only a performance breakthrough for individual products but also a technological philosophy: in the eternal conflict between efficiency and reliability, cross-disciplinary innovation finds the optimal solution. For design engineers, this device, with a diameter of only 5mm, may just be the key to unlocking the next generation of power electronic systems.

About Slkor:

SLKOR, headquartered in Shenzhen, China, is a rapidly emerging national high-tech enterprise in the power semiconductor sector. With R&D centers in Beijing and Suzhou, its core technical team originates from Tsinghua University. As an innovator in silicon carbide (SiC) power device technology, SLKOR's products are widely used in new energy vehicles, photovoltaic power generation, industrial IoT, and consumer electronics, providing critical semiconductor solutions to over 10,000 clients globally. The company delivers more than 2 billion units annually, with its SiC MOSFETs and 5th-generation ultrafast recovery SBD diodes setting industry benchmarks in efficiency ratio and thermal stability. SLKOR holds over 100 invention patents and offers 2,000+ product models, continually expanding its IP portfolio across power devices, sensors, and power management ICs. Certifications including ISO 9001, EU RoHS/REACH, and CP65 compliance demonstrate the company's steadfast commitment to technological innovation, lean manufacturing, and sustainable development.

粤公网安备44030002007346号

粤公网安备44030002007346号