Service Hotline

Shenzhen, the "Capital of Manufacturing" that has ranked first in national commodity exports for 31 years, has nurtured many outstanding foreign trade enterprises deeply rooted in manufacturing. Danyu Electronics is one of them. Its founder, Mr. Gui Xianwu, from Jiujiang, Jiangxi, successfully transitioned from an educator to an entrepreneur over twenty years. He led Danyu Electronics (Best Technology) from initially working with metal domes and circuit boards to gradually becoming a high-quality PCBA one-stop solution provider serving customers in over 60 countries and regions, winning international market recognition and trust through rapid response and reliable quality. This time, the Slkor semiconductor (www.slkoric.com) editorial team interviewed Mr. Gui Xianwu to present his journey authentically: starting with chips, establishing a foothold with quality, and focusing on providing manufacturing support services for 20 years.

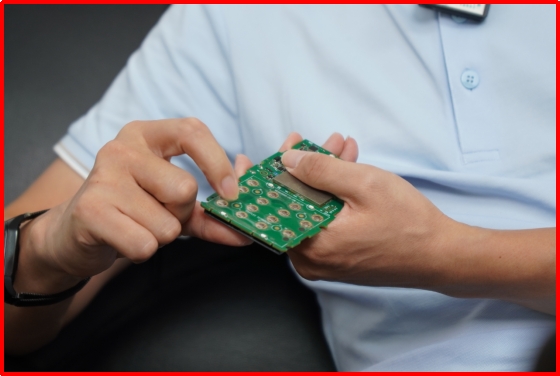

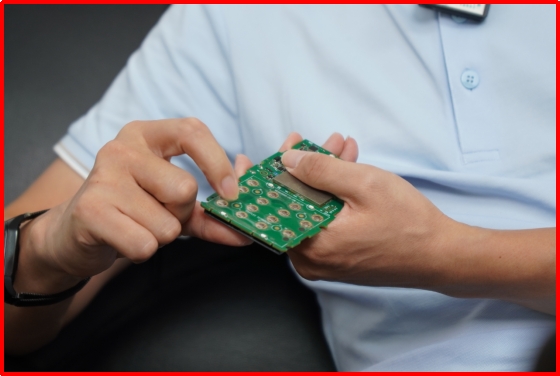

Gui Xianwu, General Manager of Shenzhen Danyu Electronics Co., Ltd.

Danyu Electronics (bestpcbs.com) was founded in 2006. Since its inception, the company has continuously expanded its capabilities based on customer needs. Each extension of its product categories has been based on precise insights into customer and market demands. "We started with metal domes. Later, when customers needed circuit boards, we began making flexible printed circuits (FPC). Then we gradually got involved in rigid boards, metal core boards, ceramic boards, and SMT assembly," introduced Gui Xianwu.

After years of development, Danyu Electronics' ceramic boards, flexible circuits, and rigid-flex boards are widely used. Ceramic boards are high-temperature resistant and have strong thermal conductivity; flexible and rigid-flex boards reduce weight while enhancing reliability, making them particularly suitable for drones, satellites, and aerospace equipment. Manager Gui proudly stated: "If you want ceramic boards domestically, you can come to us. Now, our Danyu Electronics does this exceptionally well."

Gui Xianwu introduces the circuit boards produced by the company

Danyu Electronics Product Application Scenario - Drone

Danyu Electronics has a very clear positioning: it does not independently develop its own products nor competes with customers, focusing solely on being the most reliable manufacturing service provider behind its clients. Gui Xianwu has invested in 5 factories in China specifically to produce products for the company's clients. These factories are not only equipped with new YAMAHA equipment, quality inspection instruments, etc., but in 2021, he also established Shenzhen Yutesi Electronics Co., Ltd., setting up 4 fully automatic high-speed SMT production lines to flexibly handle orders of different scales.

Gui Xianwu is particularly optimistic about the potential of the small and medium batch market. He believes that while such orders may not be large in scale, they are crucial for startups and small-to-medium enterprises. He explained: "These clients need not just products, but a reliable partner who can quickly respond to their requirements and provide high-quality products and services." And Danyu Electronics is able to serve these clients.

Danyu Electronics China SMT Workshop

From circuit board design, component procurement, assembly processing, to hand soldering, programming, testing, and assembly, Danyu Electronics provides full-turnkey services (components and assembly), especially excelling in fields like medical, automotive, aerospace, and industrial control, having cooperated with renowned clients like Ford Motor and NASA. Gui Xianwu said that Danyu Electronics has now established a strict quality management system and has obtained certifications such as ISO9001, IATF16949 (Automotive), and ISO13485 (Medical). Particularly with the acquisition of the AS9100D Aerospace Quality Management System certification in 2025, Danyu Electronics became one of the few PCBA enterprises in China with this qualification.

Danyu Electronics General Manager Gui Xianwu being interviewed

Danyu Electronics participates in Shanghai Electronica exhibition

At Danyu, there are also strict requirements for product production control. The company initiates a rigorous control process from the customer drawing evaluation stage, identifying potential issues in advance through DFM engineering analysis, and strictly inspecting incoming material quality in the IQC stage using equipment like X-Ray. During production, they insist on pre-production meeting analyses, first article confirmation, and full-process quality tracking, while also introducing 3D AOI equipment to accurately inspect the placement process, effectively preventing defects such as component misplacement, missing parts, and cold solder joints. Gui Xianwu stated: "Precisely because we implement strict quality control throughout the entire process, we dare to promise customers a one-year warranty and have full confidence in our product quality."

Internal staff carefully analyzing product situation

Internal company quality inspection process

Speaking about changes in the international trade environment in recent years, Gui Xianwu has his own coping strategies. He planned to establish a presence in Vietnam as early as 2021 and officially set up a factory there in 2024. Currently, the Vietnam factory has three dual-track Panasonic high-speed SMT lines and one wave soldering line, with a monthly capacity of 150 million points. Gui Xianwu admitted that operating a factory in Vietnam faces many difficulties, including the relatively low technical level of local workers and low government efficiency. However, he believes that with the large influx of Chinese companies into Vietnam, the overall efficiency and technical level there are gradually improving. He predicts that in the next 5 to 10 years, the operational efficiency of the Vietnam factory will approach domestic levels.

Danyu Electronics' SMT workshop in Vietnam

Gui Xianwu (first from right) posing with international clients

As the founder and general manager of Danyu Electronics, Gui Xianwu has always emphasized the importance of learning. He not only requires the sales team to possess the professional素养 of "half an engineer" to directly answer customer technical questions but also actively promotes company upgrades, planning to introduce an MES system in 2025 to comprehensively improve production management efficiency. Simultaneously, he proactively embraces new media, building personal and corporate IP through short video platforms (Video Channel: Yutesi Electronics Brother Gui), and sharing IP building experiences in Huaqiang Lecture Hall, continuously leading the team to learn new technologies and knowledge, and constantly enhancing Danyu Electronics' brand influence in the industry.

Danyu Electronics Whole staff training

Gui Xianwu sharing experience on building IP at Huaqiang Lecture Hall

From the school podium in Jiangxi to a foreign trade entrepreneur, reviewing the nearly 20-year entrepreneurial journey, Gui Xianwu believes that corporate credibility, responsibility, and accountability are the foundation. "There are no shortcuts in manufacturing. Only by doing products well and providing good service can we win customers' long-term trust." He stated that he would maintain his original aspiration in the future, continue to bring products with more "best" characteristics to customers, and persist in becoming the world's most trusted rapid provider of one-stop electronic circuit solutions. Here, Song Shiqiang, General Manager of Kinghelm and Slkor (www.slkormicro.com), wishes Danyu Electronics continued success and development, working together to provide excellent products and technical services for the global manufacturing industry!

粤公网安备44030002007346号

粤公网安备44030002007346号