Service Hotline

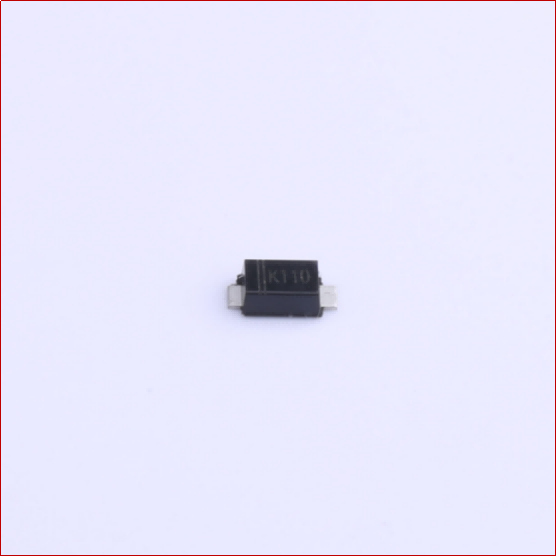

In today’s fast-paced technological world, the demand for efficiency and responsiveness in electronic systems has become nearly relentless. From smartphones to electric vehicles, from data centers to industrial automation, every incremental improvement in energy efficiency can spark industry-wide transformation. In this efficiency revolution, Slkor’s DSK110 Schottky diode has emerged as a "power tool" for many engineers, thanks to its outstanding performance. How does it drive modern electronic systems to the next level? Let’s dive into the details.

The Efficiency DNA: A Dual Performance of Low Forward Voltage and Fast Response

The DSK110’s core advantage lies in its perfect combination of low forward voltage drop (Vf=850mV@1A) and ultra-fast reverse recovery time. In power conversion applications, traditional diodes suffer from relatively high forward voltage drop, which continuously wastes energy. In contrast, the DSK110’s 0.85V drop significantly reduces energy loss. Take a 1A current switch-mode power supply as an example: using a conventional diode, power loss could exceed 1.2W, while the DSK110 reduces the loss to just 0.85W, improving efficiency by around 30%. This efficiency boost is especially critical in battery-powered devices, where less energy waste means longer battery life.

At the same time, its nanosecond-level reverse recovery time allows the DSK110 to excel in high-frequency switching applications. In motor control systems, fast response minimizes torque ripple and improves system stability; in 5G communication equipment, the high-frequency signal processing requires components with extremely short switching delays, which the DSK110 delivers, meeting the rigorous demands for signal rectification and shaping.

Reliability as a Fortress: Stability Built on Rigorous Testing

The long-term stability of electronic systems relies on the reliability of components. Slkor has built a robust defense for the DSK110 through a three-tiered quality control system:

1. Material selection: High-purity semiconductor materials minimize leakage currents caused by impurities.

2. Process Control: Precise packaging techniques ensure seamless connection between the chip and leads, reducing contact resistance.

3. Environmental Testing: The device undergoes extreme temperature cycling from -55°C to 150°C to verify its stability in complex environments.

This relentless focus on reliability has made the DSK110 shine in automotive electronics. In in-vehicle power management systems, it must withstand high temperatures and vibrations from the engine compartment. With a 100V DC reverse voltage rating and a reverse current of 500μA at 100V, the DSK110 ensures stable output even under voltage fluctuations or transient shocks.

Covering All Applications: An Efficiency Revolution from Consumer Electronics to Industrial Control

The versatility of the DSK110 goes far beyond a single industry, making it the "universal key" for multiple sectors:

- Power Management: In fast-charging adapters, the DSK110’s high-efficiency rectification reduces charging time and heat generation.

- Motor Drives: In industrial servo systems, its rapid switching reduces energy loss during motor commutation, enhancing energy efficiency.

- Communication Equipment: In 5G base stations, low-loss components are essential for high-frequency signal processing, and the DSK110’s low forward voltage drop minimizes signal attenuation.

- Automotive Electronics: From Battery Management Systems (BMS) to On-Board Chargers (OBC), the DSK110’s high reliability ensures driving safety.

Take electric vehicles as an example: their BMS must monitor battery status in real-time and adjust charge/discharge strategies. As a key rectifying component, the DSK110 must not only withstand high voltages (such as a 100V DC reverse voltage rating) but also maintain low losses during frequent switching. Slkor’s test data shows that after 100,000 switching cycles, the DSK110’s performance degrades by less than 1%, well above the industry average.

Design Guidelines: Efficiency Optimization from selection to Layout

While the DSK110 boasts excellent performance, proper design remains crucial for unlocking its full potential. Engineers should pay attention to the following points:

1. Parameter Matching: Ensure the operating current (1A average rectified current) and voltage (100V reverse voltage rating) do not exceed the limits, avoiding overheating or breakdown.

2. Thermal Design: In high-power scenarios, increasing copper foil area or using heatsinks can help reduce junction temperature.

3. Layout Optimization: Minimize trace length and reduce parasitic inductance to suppress switching noise and improve signal integrity.

4. Datasheets as a Guide: Slkor provides detailed SPICE models and thermal resistance parameters to aid engineers in accurate simulations.

Slkor: Writing the Future of Efficiency with Technology

The creation of the DSK110 epitomizes Slkor’s “Technology-Driven Innovation” philosophy. The company invests 15% of its annual revenue in R&D and holds over 50 semiconductor patents, with a product line spanning diodes to power MOSFETs. More notably, Slkor has established a full-lifecycle quality traceability system, ensuring that every DSK110 can be traced back to its raw material batch and manufacturing process. This commitment to quality has made Slkor the partner of choice for over 3,000 global customers.

Conclusion: Small Component, Big Revolution

The story of the DSK110 Schottky diode is a prime example of the semiconductor industry’s “small but mighty” philosophy. With a 0.85V voltage drop, nanosecond-level response time, and million-cycle reliability, it redefines the boundaries of efficiency and stability. In the face of both the energy crisis and the push for carbon neutrality, the DSK110 is not just a tool for engineers but a key enabler of green technology. As new materials like SiC continue to emerge, the DSK110’s evolutionary journey will persist, and Slkor is prepared to remain at the forefront of this efficiency revolution.

About Slkor:

SLKOR, headquartered in Shenzhen, China, is a rapidly emerging national high-tech enterprise in the power semiconductor sector. With R&D centers in Beijing and Suzhou, its core technical team originates from Tsinghua University. As an innovator in silicon carbide (SiC) power device technology, SLKOR's products are widely used in new energy vehicles, photovoltaic power generation, industrial IoT, and consumer electronics, providing critical semiconductor solutions to over 10,000 clients globally. The company delivers more than 2 billion units annually, with its SiC MOSFETs and 5th-generation ultrafast recovery SBD diodes setting industry benchmarks in efficiency ratio and thermal stability. SLKOR holds over 100 invention patents and offers 2,000+ product models, continually expanding its IP portfolio across power devices, sensors, and power management ICs. Certifications including ISO 9001, EU RoHS/REACH, and CP65 compliance demonstrate the company's steadfast commitment to technological innovation, lean manufacturing, and sustainable development.

粤公网安备44030002007346号

粤公网安备44030002007346号